Infrared Cameras Revolutionizing HVAC Industry

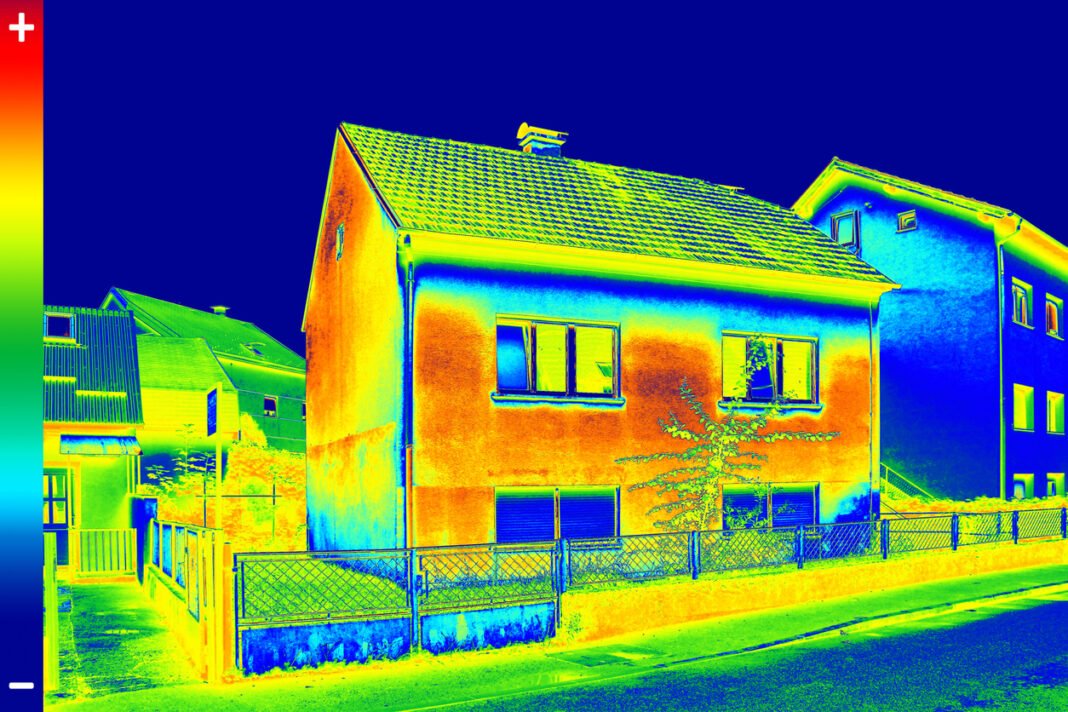

In the rapidly evolving world of heating, ventilation, and air conditioning (HVAC), the integration of infrared (IR) camera technology is reshaping how professionals diagnose, maintain, and optimize HVAC systems. These advanced thermal imaging tools provide a non-invasive, precise, and highly efficient method for assessing system performance, identifying issues, and improving energy efficiency.

A Game-Changer for HVAC Maintenance

Detecting Air Leaks and Insulation Deficiencies

Energy loss due to air leaks and poor insulation is a major concern in both residential and commercial HVAC systems. Infrared cameras allow technicians to detect temperature variances along ductwork, walls, and insulation barriers, ensuring leaks are addressed before they lead to excessive energy waste.

Preventing Costly Equipment Failures

HVAC systems operate with numerous electrical and mechanical components, including compressors, motors, and wiring. Overheated components can signal impending system failure. With infrared cameras, maintenance teams can identify hotspots and replace worn-out parts before breakdowns occur, reducing downtime and repair costs.

Efficient Ductwork Inspection

Traditional duct inspections can be time-consuming and disruptive. Infrared cameras provide a quick and effective method to locate leaks, blockages, or inefficiencies in HVAC ducts without requiring physical disassembly, ensuring better air distribution and lower utility costs.

Ensuring Proper Airflow and Ventilation

Indoor air quality is directly linked to HVAC system performance. Poor airflow can lead to uneven temperature distribution and increased energy consumption. Infrared imaging helps technicians assess airflow irregularities, allowing for precise recalibration of vents and ducts.

Revolutionizing Preventive Maintenance

Infrared cameras are playing a pivotal role in predictive maintenance, enabling professionals to identify hidden problems before they escalate into costly repairs. By regularly scanning HVAC systems, technicians can ensure optimal efficiency, lower operational costs, and prolonged equipment lifespan.

Monitoring Refrigerant Levels and Performance

Refrigerant issues can cause inefficient cooling and increased energy demand. Infrared technology allows for quick detection of temperature inconsistencies in condenser and evaporator coils, ensuring refrigerant levels are balanced for maximum efficiency.

A Vision for the Future

As the HVAC industry embraces smart technology and AI-driven solutions, infrared cameras are becoming more advanced, offering higher resolution, wireless capabilities, and AI-enhanced diagnostics. These innovations are making HVAC systems smarter, more energy-efficient, and environmentally friendly.