1. What is Pressurization?

Pressurization is the process of maintaining controlled air pressure differentials between different zones or between the inside and outside of a building by controlling supply air, return air, and exhaust air.

- If Supply Air > Exhaust Air → Positive Pressure

- If Exhaust Air > Supply Air → Negative Pressure

- If Supply = Exhaust → Neutral Pressure

This principle is fundamental for indoor air quality, comfort, safety, and infection control.

2. Why Pressurization Matters

- Air Quality Control: Prevents infiltration of polluted outdoor air.

- Comfort: Keeps hot, humid, or dusty air from entering occupied zones.

- Infection Control: Directs air movement in hospitals (clean → less clean → dirty areas).

- Odor Control: Stops transfer of smells (kitchen, toilets, labs).

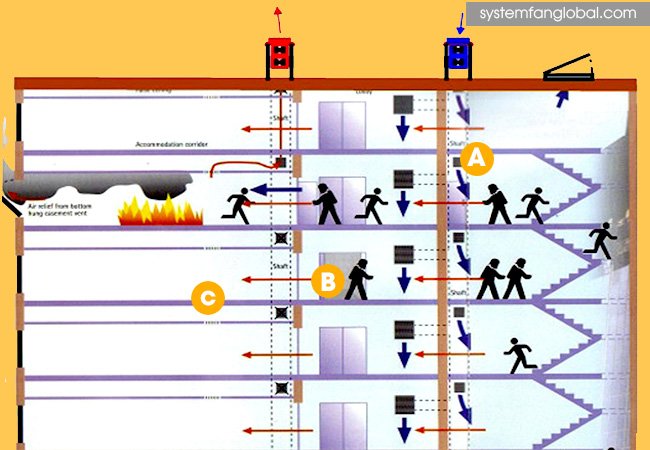

- Fire & Life Safety: Maintains safe escape routes (pressurized stairwells, lift lobbies).

3. Types of Pressurization

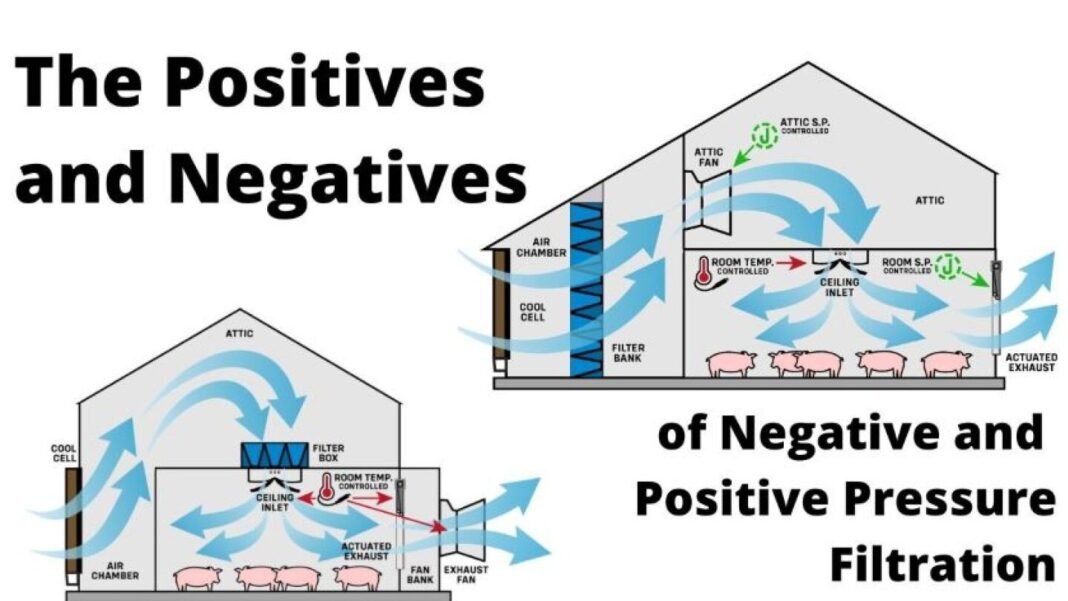

🔹 Positive Pressure

- Supply air is greater than exhaust.

- Air flows out of the space when doors open.

- Applications:

- Office spaces (to keep dust out).

- Hospital operating rooms, ICUs.

- Data centers, clean rooms.

- Lift lobbies, escape corridors (fire safety).

🔹 Negative Pressure

- Exhaust air is greater than supply.

- Air flows into the space when doors open.

- Applications:

- Toilets, bathrooms, kitchens.

- Isolation rooms (infectious diseases).

- Laboratories handling chemicals or biohazards.

- Garbage rooms.

🔹 Neutral Pressure

- Supply ≈ Exhaust.

- Balanced environment where minimal air transfer is desired.

- Applications:

- General office spaces (with mixed air systems).

- Storage areas.

- Public zones with no contaminants.

4. Pressurization in Different Buildings

- Hospitals:

- Operating Room → Positive pressure (clean air flows outward).

- Isolation Room → Negative pressure (contaminated air is contained).

- High-Rise Towers:

- Stairwells and lift lobbies pressurized for fire safety.

- Apartments/rooms slightly positive vs. corridors.

- Industrial Facilities:

- Clean zones positive vs. production halls.

- Hazardous process areas kept negative.

5. Typical Pressure Differentials

- General comfort: +5 to +10 Pa (positive).

- Healthcare critical zones: +15 Pa (OR positive), -15 Pa (Isolation negative).

- Stairwell pressurization (fire): +25 to +50 Pa to prevent smoke infiltration.

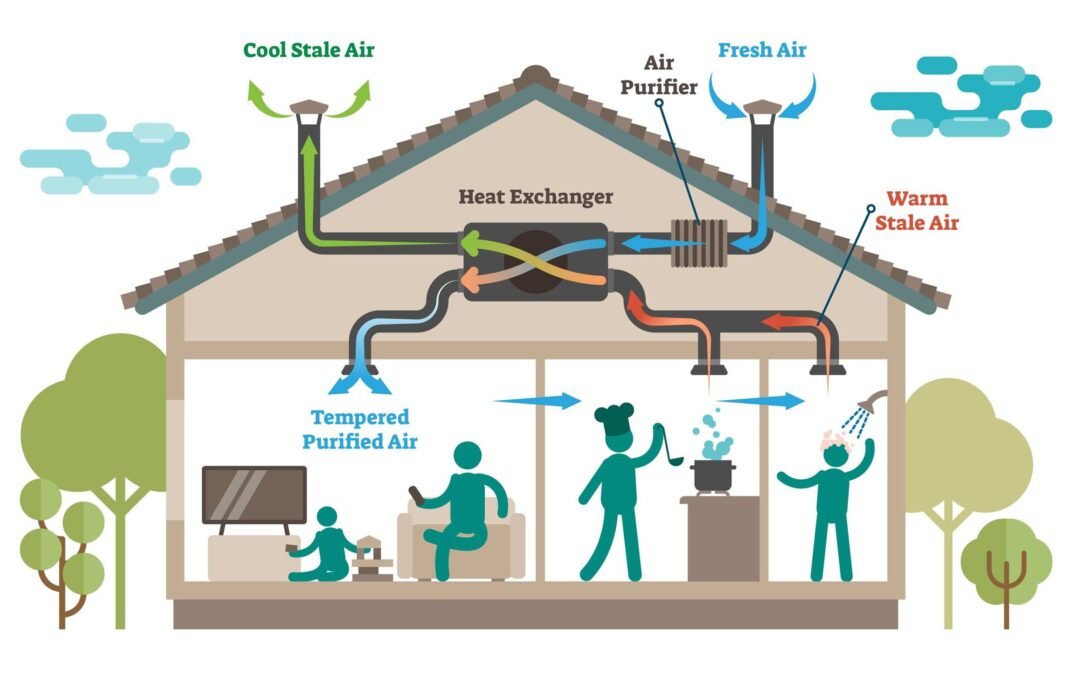

6. How FAHUs Support Pressurization

- Supply Control: FAHU delivers conditioned outdoor air.

- Exhaust Balancing: Coordinated exhaust fans maintain desired pressure.

- BMS Integration: Pressure sensors + differential pressure transmitters control dampers and fan speeds.

- Energy Recovery: In high outdoor air demand zones, heat recovery devices reduce energy penalty.

7. Example Scenarios

- Hospital ICU: FAHU supplies 100% fresh air, maintaining positive pressure in corridors, negative pressure in isolation rooms.

- Commercial Tower: FAHU pressurizes lift lobbies and staircases to ensure fire safety.

- Industrial Lab: FAHU supplies controlled air, while fume hoods exhaust to maintain negative pressure.