1. What is a Mixing Box?

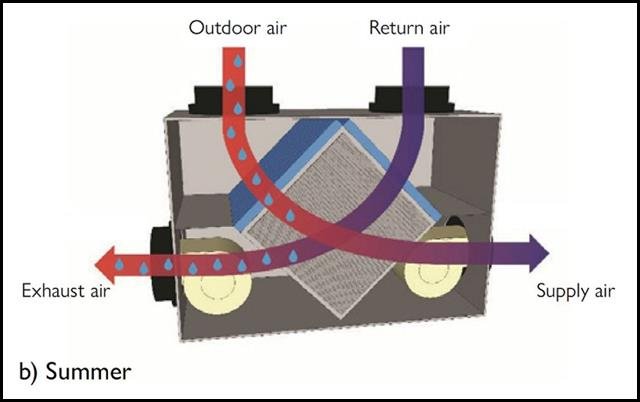

- A mixing box is a section inside an AHU (or hybrid FAHU) where outdoor (fresh) air and return air from the building are mixed in controlled proportions before further conditioning.

- Equipped with dampers and sometimes actuators, it helps optimize IAQ, energy efficiency, and pressurization.

👉 Note: In a true FAHU (100% outdoor air), there is usually no return air mixing. Mixing boxes are mostly in AHUs or FAHUs with partial return-air operation (energy-saving designs).

2. Purpose of a Mixing Box

- Ventilation Control: Ensures correct fresh air percentage as per ASHRAE 62.1 / local codes.

- Energy Efficiency: Reduces energy use by mixing conditioned return air with fresh air.

- Pressurization Control: Helps maintain positive/negative pressure in zones by adjusting airflow balance.

- Flexibility: Allows operation in different modes:

- 100% fresh air (purge mode).

- 100% return air (recirculation mode).

- Mixed mode (normal operation).

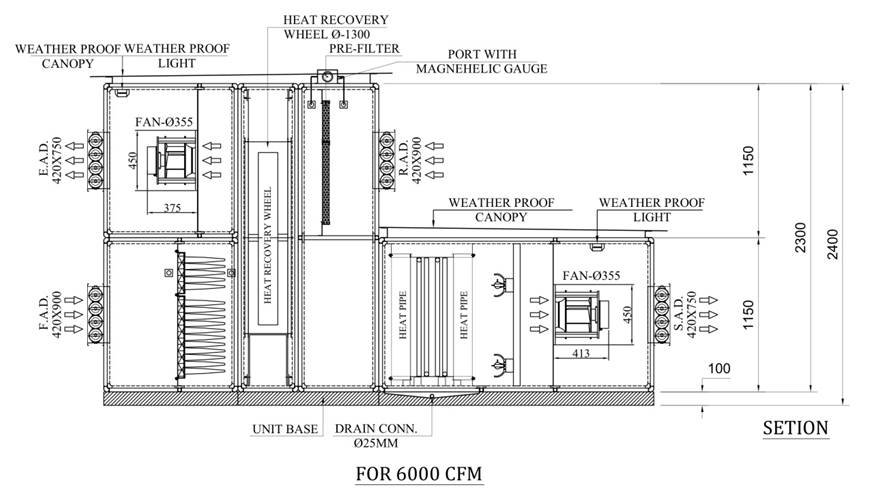

3. Components of a Mixing Box

- Fresh Air Damper: Controls the volume of outdoor air entering.

- Return Air Damper: Controls the volume of air recirculated from occupied spaces.

- Exhaust/Relief Air Damper: Balances excess air to maintain correct building pressure.

- Actuators: Motorized devices that adjust damper positions automatically.

- Mixing Section: Chamber where fresh and return air streams combine before hitting filters and coils.

4. Damper Arrangement

The typical damper arrangement includes:

- Fresh Air Damper (connected to outside air intake).

- Return Air Damper (connected to duct bringing air back from zones).

- Exhaust/Relief Damper (to discharge excess air outdoors).

👉 Dampers are interlinked (opposed blade type):

- When fresh air damper opens more, the return air damper closes proportionally, and vice versa.

- Controlled by BMS actuators for automatic modulation.

5. Modes of Operation

- Normal Mode (Mixed):

- Fresh air: ~20–30%

- Return air: ~70–80%

- Exhaust damper: opens as needed.

- 100% Fresh Air Mode (Purge):

- Fresh air damper fully open.

- Return damper closed.

- Exhaust damper fully open.

- Used in emergencies (e.g., smoke purge, contamination).

- 100% Recirculation Mode (Energy Saving):

- Return damper fully open.

- Fresh air damper closed.

- Exhaust damper closed.

- Used during unoccupied hours (not allowed for critical spaces).

6. Application Examples

- Office Buildings:

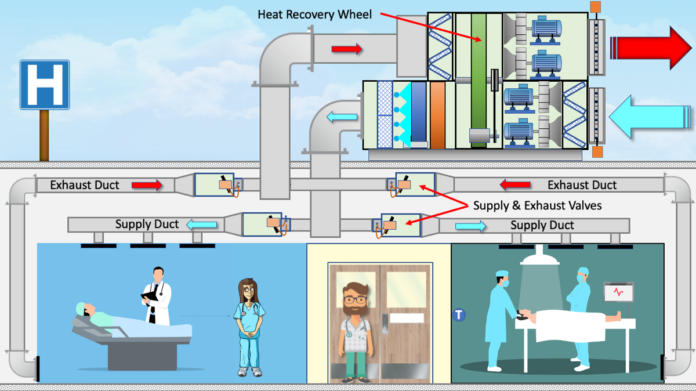

Mixing box allows 20–30% fresh air intake while reusing return air for energy savings. - Hospitals:

- Operating rooms → FAHUs supply 100% fresh air (no mixing box).

- General areas → AHUs may use mixing boxes to balance energy and IAQ.

- Industrial Facilities:

- Clean rooms use minimal or no return mixing.

- General zones may mix filtered return air.

7. Example Air Balance

For a 10,000 CFM AHU:

- Fresh air damper → 2,000 CFM (20%).

- Return air damper → 8,000 CFM (80%).

- Exhaust damper → balances excess to maintain neutral/positive pressure.

8. Key Design Considerations

- Dampers must be low leakage type for accuracy.

- Proper air sealing in mixing box is essential to prevent bypass.

- Differential pressure sensors may be used to monitor outside vs. inside airflow.

- Mixing should be even to prevent hot/cold spots on coils (use baffles or air mixers if needed).