1. What is Pressure Drop?

- Definition: Pressure drop is the resistance to airflow caused by FAHU components such as filters, coils, dampers, and duct connections.

- Units: Pascals (Pa) or Inches of Water Gauge (in. w.g.).

- Key Point: As components get dirty (filters clog, coils foul), pressure drop increases, airflow reduces, and the fan consumes more energy.

2. Sources of Pressure Drop in FAHU

- Filters:

- Clean pre-filter: 50–100 Pa

- Fine filter: 100–200 Pa

- HEPA filter: 250–400 Pa

- Cooling/Heating Coils: 50–100 Pa (depends on coil rows & fin density).

- Dampers & Silencers: 20–60 Pa.

- Ductwork & Accessories: Adds extra resistance to be considered in total static pressure.

3. Monitoring Pressure Drop

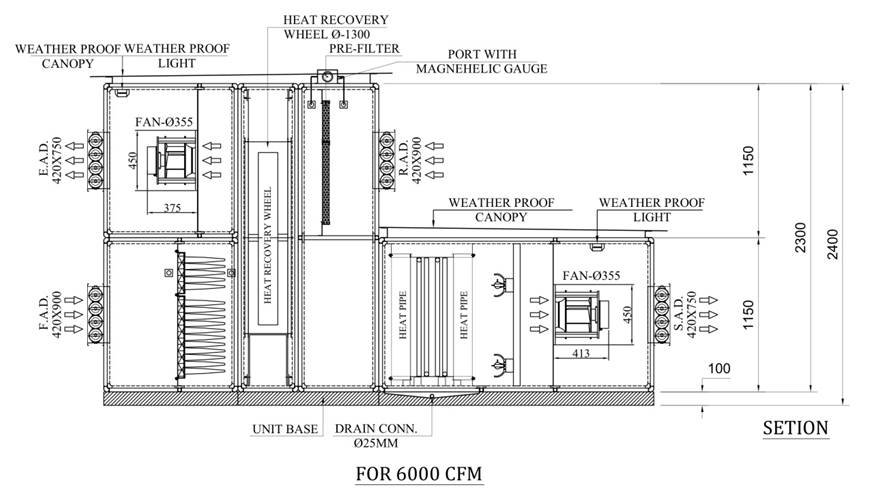

- Differential Pressure Gauges (Magnehelic): Installed across filter banks and coils.

- Differential Pressure Transmitters (DPTs): Provide real-time data to the BMS (Building Management System).

- Setpoints for Action:

- Pre-filter: Replace/clean at 150–200 Pa.

- Fine filter: Replace at 250–300 Pa.

- HEPA: Replace at >400 Pa.

- Warning: Operating with clogged filters → reduced ventilation, IAQ failure, and excessive fan energy.

4. Effects of High Pressure Drop

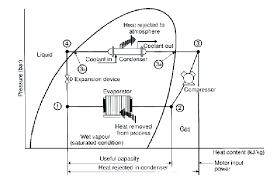

- Increased fan power consumption (higher kW demand).

- Reduced air supply → occupants feel discomfort, IAQ worsens.

- Risk of condensation & microbial growth on coils due to low airflow.

- Overheating of fan motors if prolonged.

- Shorter lifespan of filters, fans, and motors.

5. Maintenance Practices

🔹 Filters

- Pre-filters: Wash/replace every 1–3 months.

- Fine filters: Replace every 6–12 months.

- HEPA filters: Replace every 12–24 months (not washable).

- Always check ΔP across filters before replacement.

🔹 Coils

- Clean cooling/heating coils every 6–12 months to remove dust, biofilm, and scale.

- Maintain clean drain pans to avoid bacterial growth (Legionella risk).

🔹 Fans & Dampers

- Inspect fan belts, bearings, and VFDs every 3 months.

- Check damper operation and actuator calibration.

🔹 General

- Inspect casing and access doors for air leakage.

- Verify differential pressure sensors regularly.

6. Example: Office Building FAHU

- Design airflow: 10,000 CFM.

- Initial filter ΔP: 200 Pa.

- After 6 months, ΔP rises to 400 Pa → airflow drops to 7,000 CFM.

- Result: Occupants complain of “stuffy” rooms, energy bill rises due to fan overwork.

- Solution: Filter replacement restores airflow and reduces fan power.

7. Recommended Maintenance Schedule

| Component | Check Frequency | Action |

|---|---|---|

| Pre-Filters | Monthly | Wash/replace if ΔP > 150 Pa |

| Fine Filters | Quarterly | Replace if ΔP > 250 Pa |

| HEPA Filters | 6–12 months | Replace if ΔP > 400 Pa |

| Cooling/Heating Coils | Every 6 months | Clean with coil cleaner, flush drain pans |

| Fans/Blowers | Quarterly | Lubricate, check belts, vibration, VFD |

| Dampers | Quarterly | Inspect blade operation & actuators |

✅ Summary:

- Pressure drop is a key performance indicator in FAHUs.

- Monitoring with gauges/sensors ensures timely action before airflow/IAQ problems occur.

- Preventive maintenance (filters, coils, fans) reduces energy cost, maintains IAQ, and extends system life.