1. Role of Fans in FAHU

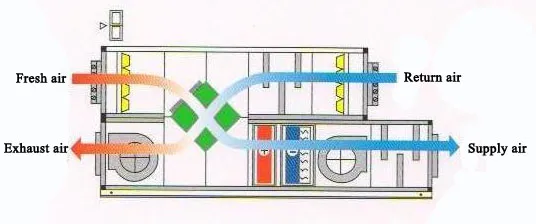

- Move conditioned outdoor air through filters, coils, and ducts into the building.

- Overcome system static pressure (filters, coils, silencers, ductwork).

- Ensure design airflow to maintain IAQ, comfort, and pressurization.

2. Types of Fans Used in FAHU

🔹 a. Centrifugal Fans

- How They Work: Air enters axially into the fan wheel and exits radially.

- Types:

- Forward-curved: Low noise, lower efficiency.

- Backward-curved: Higher efficiency, widely used in AHUs/FAHUs.

- Airfoil blades: Highest efficiency, lower noise.

- Advantages:

- High static pressure capability (500–2000 Pa).

- Robust and reliable.

- Applications: Large FAHUs, hospitals, commercial towers.

🔹 b. Plug Fans (Plenum Fans)

- How They Work: Fan wheel sits directly in the plenum (chamber) without scroll housing.

- Advantages:

- Compact, easy to integrate in modular FAHUs.

- Direct-drive (no belts) → less maintenance.

- Even airflow distribution across coil/filter face.

- Efficiency: Medium-high.

- Applications: Modern FAHUs in malls, airports, data centers.

🔹 c. EC Fans (Electronically Commutated Fans)

- How They Work: Brushless DC motors with built-in electronic control.

- Advantages:

- Very high efficiency (up to 90%).

- Variable speed control (no need for separate VFD).

- Quiet operation.

- Smaller footprint.

- Applications: Energy-efficient buildings, green projects, retrofits.

- Standards: Often used where LEED/WELL/Estidama compliance is required.

3. Fan Selection Criteria

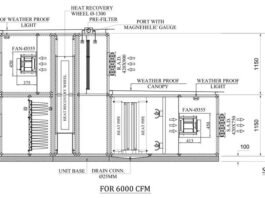

- Airflow Capacity (CFM or L/s).

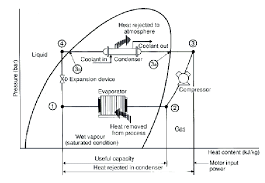

- Static Pressure Requirement (Pa or in. w.g.).

- Efficiency (fan curves).

- Noise Level (NC values for comfort spaces).

- Space/installation constraints.

- Maintenance requirements.

4. Fan Control & Integration

- VFDs (Variable Frequency Drives): Used with centrifugal/plug fans for speed control and energy saving.

- EC Fans: Have built-in speed control, BMS-ready.

- Pressure Sensors: Linked to fans to maintain constant airflow under varying filter pressure drops.

- BMS Monitoring: Energy use, alarms, and performance tracking.

5. Pressure Drop & Maintenance

- Contribution: Fans must overcome ~300–600 Pa FAHU resistance + duct pressure drop.

- Maintenance Tasks:

- Inspect bearings, belts (for belt-driven fans).

- Lubricate bearings as per manufacturer’s instructions.

- Clean fan blades and housings to avoid imbalance.

- Check vibration and noise.

- For EC fans: Check electronic boards, sensors, and clean cooling vents.

6. Comparison Table

| Fan Type | Efficiency | Pressure Capability | Noise | Maintenance | Applications |

|---|---|---|---|---|---|

| Centrifugal | Medium–High | High (500–2000 Pa) | Moderate | Moderate (belts, bearings) | Large FAHUs, hospitals |

| Plug Fan | Medium–High | Medium (300–1000 Pa) | Lower | Low (direct-drive) | Modular FAHUs, data centers |

| EC Fan | Very High | Medium (300–1000 Pa) | Very Low | Very Low (no belts) | Energy-efficient, green buildings |

7. Example Applications

- Hospital FAHU: Centrifugal backward-curved fans to handle high filter pressure (HEPA).

- Shopping Mall FAHU: Plug fans for large airflow and even coil face distribution.

- Office Tower FAHU (LEED Certified): EC fans for maximum energy efficiency and BMS integration.