1. Role of Coils in FAHU

- FAHUs handle 100% outdoor air, which must be conditioned before supply.

- Cooling Coils → reduce temperature and remove humidity.

- Heating Coils → increase temperature or reheat dehumidified air.

- Together, they ensure thermal comfort, humidity control, and process requirements.

2. Cooling Coils

Function

- Lower the temperature of hot outdoor air.

- Condense and remove excess moisture (dehumidification).

- Maintain comfort and IAQ by supplying air within set temperature & humidity.

Types

- Chilled Water (CHW) Coil:

- Uses chilled water from central chiller plant.

- Common in large commercial/industrial systems.

- Direct Expansion (DX) Coil:

- Uses refrigerant (R-410A, R-32, etc.) from condensing unit.

- Used in smaller systems or where no chiller plant exists.

Design Considerations

- Capacity: Based on required cooling load (sensible + latent).

- Face Velocity: Typically 2–2.5 m/s (400–500 FPM).

- Rows of Tubes: 4–8 rows depending on load.

- Fin Material: Aluminum (common), Copper (better conductivity, higher cost).

- Condensate Drain Pan: Must be sloped and corrosion-resistant to avoid water carryover.

3. Heating Coils

Function

- Heat cold outdoor air in winter climates.

- Provide reheat after dehumidification (for humidity control).

- Maintain minimum supply air temperature to occupied zones.

Types

- Hot Water Coil:

- Uses hot water from boiler or district heating.

- Steam Coil:

- Uses steam (industrial applications, cold climates).

- Electric Heater Coil:

- Used where hot water/steam is not available (backup heating).

Design Considerations

- Supply Air Temperature: Usually 20–22°C (68–72°F) in comfort applications.

- Materials: Copper tubes, aluminum fins, galvanized/stainless casing.

- Freeze Protection: Required for coils in cold climates (glycol mixture or preheat coil).

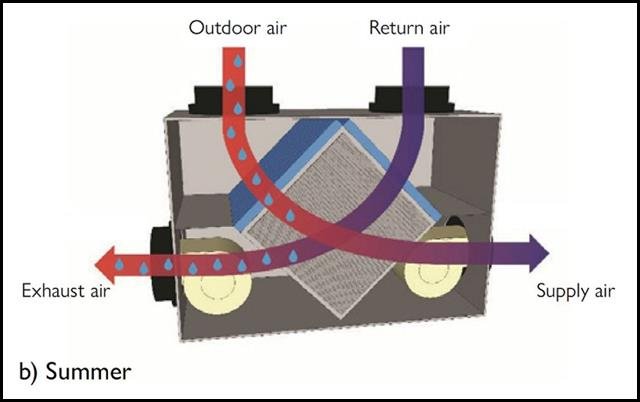

4. Psychrometric Role

- Cooling Coil Process: Air follows a cooling + dehumidification line on the psychrometric chart (downward & left).

- Heating Coil Process: Air follows a sensible heating line (upward, constant humidity ratio).

- Reheat Process: After deep dehumidification, heating coil raises dry-bulb temperature without adding moisture.

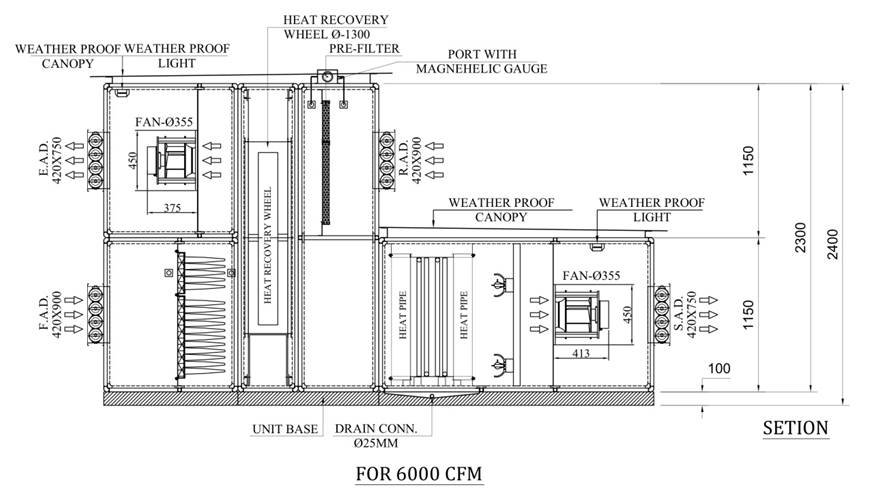

5. Coil Placement in FAHU

- Filter → Cooling Coil → Heating Coil → Fan

- Cooling coils are placed before fans to handle conditioned air.

- Heating coils may be:

- Preheat coils (before filters) → prevent freezing in cold climates.

- Reheat coils (after cooling coil) → humidity & comfort control.

6. Pressure Drop & Maintenance

- Cooling coils: Add 50–100 Pa pressure drop.

- Heating coils: Add 30–70 Pa pressure drop.

- Maintenance:

- Regular coil cleaning to prevent fouling (dust, biofilm).

- Ensure drain pans are clean to avoid microbial growth.

- Inspect fins & straighten bent sections.

7. Applications

- Office Buildings: Cooling coil (CHW/DX) + optional reheat coil.

- Hospitals: Cooling coil for temperature + humidity control, reheat coil for sterile supply.

- Cold Regions: Preheat coil to prevent frosting of filters and coils.

- Pharma/Labs: Combination of cooling + heating coils for precise air treatment.

8. Example Case

- Outdoor Air: 38°C DB / 26°C WB (hot-humid climate).

- Desired Supply: 22°C DB / 50% RH.

- Cooling Coil: Drops air to 14°C (dehumidification to remove moisture).

- Heating Coil (Reheat): Raises air back to 22°C at ~50% RH → comfort condition.