1. Pressure Drop Across Coils

When air passes through cooling or heating coils, resistance is created due to fins, tubes, and condensate on coil surfaces.

- Cooling Coils:

- Pressure Drop (Clean Coil): 50–100 Pa (0.2–0.4 in. w.g.)

- Higher for deep coils (6–8 rows) and high face velocity (>2.5 m/s).

- Additional drop occurs when wet (condensate increases resistance).

- Heating Coils:

- Pressure Drop (Clean Coil): 30–70 Pa (0.1–0.3 in. w.g.)

- Typically lower than cooling coils because no condensation forms.

- Impact of Fouling:

- Dust, grease, and microbial growth increase resistance dramatically.

- Results in reduced airflow, higher fan power, poor cooling/heating capacity.

2. Monitoring Coil Performance

- Differential Pressure Gauges/Sensors: Installed across coils to measure resistance.

- Temperature Sensors: Supply vs. return air temperature difference indicates coil performance.

- Signs of Problem:

- ΔP across coil rises above design by >50%.

- Supply air temperature fails to meet setpoint.

- Uneven air distribution (hot/cold spots).

3. Coil Maintenance Practices

🔹 Cooling Coils

- Cleaning Frequency: Every 6–12 months (quarterly in dusty/humid climates).

- Methods:

- Vacuuming/Brushing: For light dust.

- Low-pressure water washing from upstream side.

- Chemical Coil Cleaners (non-acidic, biodegradable) for stubborn dirt and biofilm.

- Drain Pan & Traps:

- Must be cleaned to prevent microbial growth (Legionella risk).

- Ensure slope & P-trap are functional to avoid water carryover.

🔹 Heating Coils

- Less prone to fouling (no condensation), but still collect dust.

- Clean with vacuum and soft brushing every 6–12 months.

- In cold climates:

- Inspect for freezing damage.

- Use glycol mix in hot water coils for freeze protection.

- Provide preheat coils to protect downstream filters.

4. Preventive Measures

- Ensure filters are well maintained → prevents dust reaching coils.

- Maintain face velocity within design (≤2.5 m/s) to minimize carryover.

- Apply anti-microbial coating in healthcare facilities.

- Use UV-C lamps upstream of coils to continuously disinfect and reduce biofilm.

5. Effects of Neglected Coil Maintenance

- Cooling Coil:

- Clogged fins → reduced airflow & cooling.

- High fan energy consumption.

- Increased humidity due to poor dehumidification.

- Risk of mold growth → poor IAQ.

- Heating Coil:

- Reduced heating efficiency in winter.

- Frozen coils (if not protected) → rupture of tubes.

- Higher pump energy due to scale in water circuits.

6. Typical Maintenance Schedule

| Coil Type | Check Frequency | Action |

|---|---|---|

| Cooling Coils | Quarterly (dusty climate) / Bi-annual (normal) | Clean fins, flush drain pans, check condensate traps |

| Heating Coils | Bi-annual | Clean fins, check for leaks, ensure freeze protection |

| Drain Pan | Monthly | Disinfect & clean standing water |

| UV-C Lamps (if used) | Annually | Replace lamps for effective microbial control |

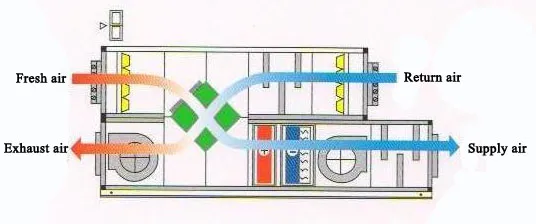

7. Example: FAHU in a Hot-Humid Climate

- Outdoor air: 40°C DB / 28°C WB.

- Cooling coil ΔP design: 80 Pa.

- After 6 months of neglect, ΔP rises to 180 Pa, airflow drops by 25%.

- Result: Supply air temperature increases from 14°C to 18°C, humidity control fails.

- After coil cleaning, ΔP returns to 85 Pa, design conditions restored.