1. Why Heat Recovery?

- FAHUs handle 100% fresh outdoor air.

- In hot-humid climates (e.g., Middle East, Asia), this air requires significant cooling and dehumidification.

- In cold climates, outdoor air needs heating and humidification.

- Without recovery, this is highly energy-intensive.

- Heat Recovery Systems (HRS) transfer energy between exhaust air (leaving the building) and fresh air (entering the building), reducing the load on cooling/heating coils.

2. Benefits of Heat Recovery

- Energy Efficiency: 20–70% energy savings (depending on system).

- Reduced Operating Cost: Cuts cooling/heating plant loads.

- Improved IAQ: Allows higher ventilation rates without huge energy penalties.

- Sustainability: Supports LEED, WELL, Estidama, and Vision 2030 green building goals.

- Mandatory in Codes: Many regions (UAE, Qatar, Saudi) require heat recovery in FAHUs with >20% outdoor air fraction.

3. Types of Heat Recovery Systems

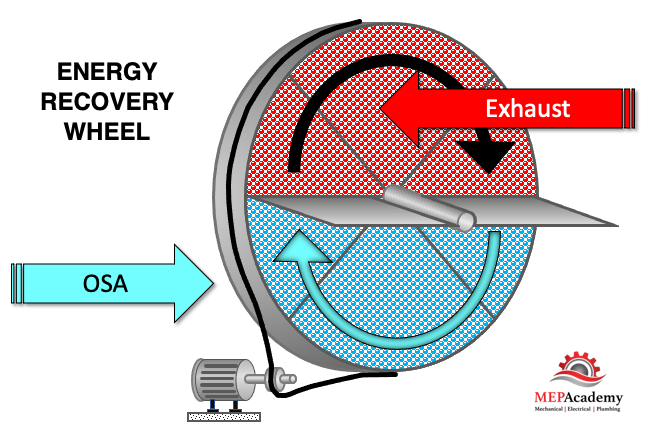

🔹 a. Rotary Energy Recovery Wheel (Enthalpy Wheel)

- Rotating wheel made of heat-absorbing material.

- Transfers sensible (temperature) + latent (moisture) energy.

- Efficiency: 70–80%.

- Applications: Offices, malls, airports.

- Pros: High efficiency, compact.

- Cons: Possible cross-contamination if not sealed properly.

🔹 b. Plate Heat Exchanger

- Parallel plates separate supply and exhaust air streams.

- Transfers only sensible heat (temperature).

- Efficiency: 50–70%.

- Applications: Hospitals, cleanrooms (no cross-contamination).

- Pros: No moving parts, hygienic.

- Cons: No latent transfer, larger footprint.

🔹 c. Heat Pipe Heat Exchanger

- Uses sealed copper tubes with refrigerant.

- Transfers heat by evaporation–condensation cycle.

- Efficiency: 45–65%.

- Applications: Compact FAHUs, data centers.

- Pros: Simple, reliable, no moving parts.

- Cons: Only sensible transfer, orientation-dependent.

🔹 d. Run-Around Coil System

- Two separate coils (one in exhaust, one in supply), connected by water/glycol loop with pump.

- Efficiency: 45–60%.

- Applications: When supply and exhaust ducts are far apart.

- Pros: No cross-contamination, flexible layout.

- Cons: Lower efficiency, higher maintenance (pump, piping).

4. Comparison Table

| System | Heat Type | Efficiency | Cross-Contamination Risk | Best For |

|---|---|---|---|---|

| Rotary Wheel | Sensible + Latent | 70–80% | Medium (if leakage occurs) | Offices, malls |

| Plate Heat Exchanger | Sensible Only | 50–70% | Very Low | Hospitals, labs |

| Heat Pipe | Sensible Only | 45–65% | None | Data centers, compact FAHUs |

| Run-Around Coil | Sensible Only | 45–60% | None | Separated exhaust/supply ducts |

5. Example: Office Tower in Hot Climate (Dubai/Qatar)

- Outdoor air: 42°C DB, 26°C WB.

- Indoor air: 24°C, 50% RH.

- FAHU with rotary wheel recovers cooling energy from exhaust air at 24°C → reduces entering air load to ~30°C before it hits cooling coil.

- Result: 30–40% reduction in chiller load.

6. Example: Hospital (Clean Zone)

- FAHU uses plate heat exchanger to recover sensible energy from exhaust air without risk of contamination.

- Maintains sterile air supply while saving 25–30% cooling/heating energy.

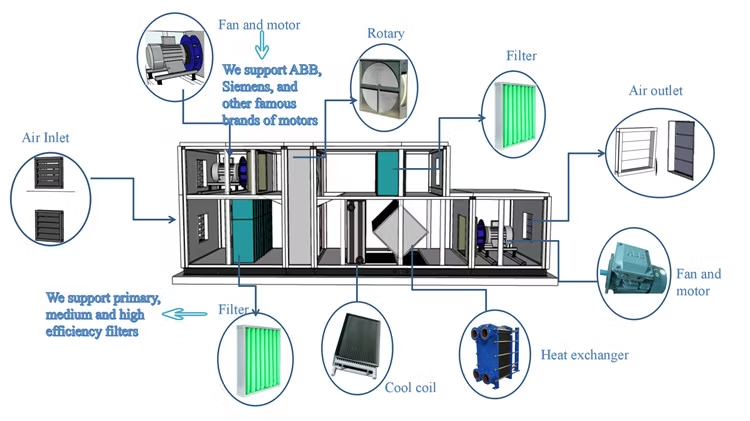

7. Integration with BMS & VFDs

- Sensors monitor temperature, humidity, airflow.

- BMS logic controls wheel rotation speed, pump flow, or bypass dampers.

- VFDs adjust fan speed to account for added pressure drop across heat recovery devices.