1. What is Pressure Drop?

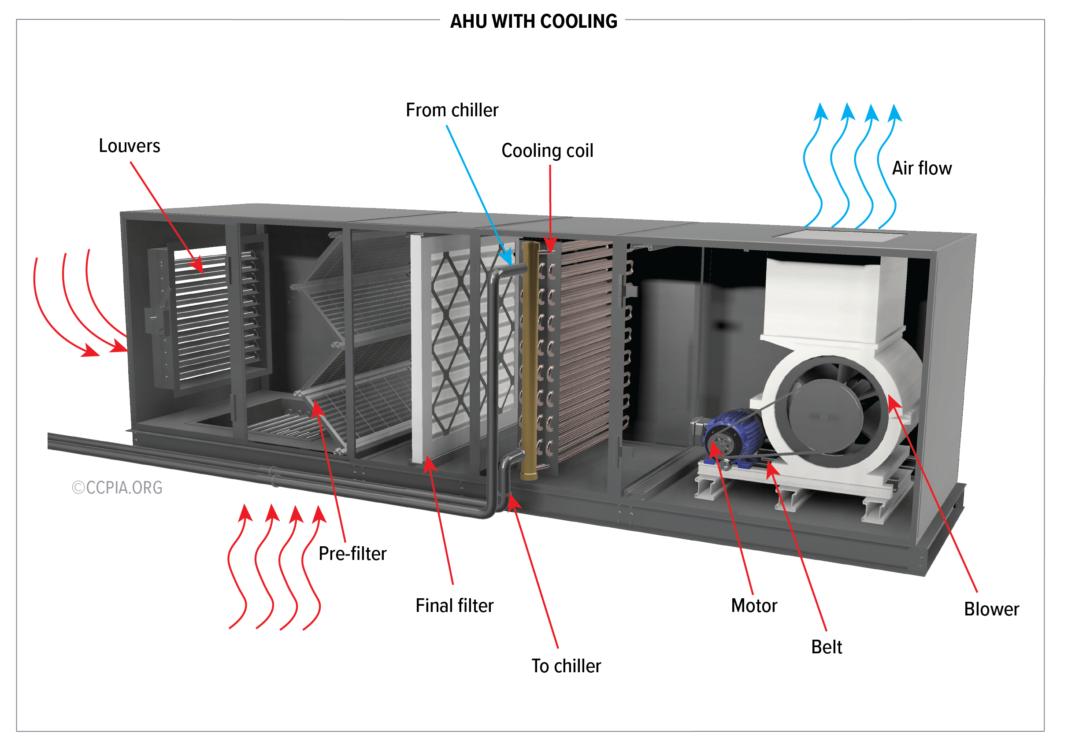

- Definition: Pressure drop is the resistance to airflow caused by components inside the FAHU — mainly filters, coils, and dampers.

- Unit of Measurement: Usually in Pascals (Pa) or inches of water gauge (in. w.g.).

- Impact:

- Higher pressure drop → higher fan power required.

- Increases energy consumption.

- Indicates filter clogging or dirty coils.

2. Pressure Drop Across Filters

Filters are the main contributors to FAHU pressure drop.

- Pre-Filters: 50–100 Pa (0.2–0.4 in. w.g.)

- Fine Filters (F7–F9): 100–200 Pa (0.4–0.8 in. w.g.)

- HEPA Filters: 250–400 Pa (1.0–1.6 in. w.g.)

🔹 As filters get dirty, their pressure drop increases significantly. This is why monitoring is essential.

3. Monitoring Pressure Drop

- Differential Pressure Gauges (Magnehelic gauges):

Installed across filter banks, showing clean vs. dirty filter resistance. - Differential Pressure Sensors (DPTs):

Provide signals to BMS for real-time monitoring and alarms. - Setpoints:

- Pre-filter replacement: 150–200 Pa

- Fine filter replacement: 250–300 Pa

- HEPA replacement: >400 Pa

4. Maintenance Practices

🔹 Filters

- Pre-filters: Washable, cleaned every 1–3 months, replaced every 6–12 months.

- Fine filters: Replaced every 6–12 months.

- HEPA filters: Replaced every 1–2 years (cannot be washed).

🔹 Coils

- Need periodic cleaning to avoid fouling and biofilm growth (which increases pressure drop and reduces heat transfer).

- Cleaning frequency: 6–12 months depending on application.

🔹 Fans & Ducts

- Fans should be checked for balance and bearing wear.

- Ducts inspected for leakage and dust accumulation.

5. Effects of High Pressure Drop

- Increased fan energy consumption.

- Reduced airflow → poor IAQ, discomfort, and code violations.

- Shortened filter life and increased maintenance cost.

- Risk of bypass air if filters are not sealed properly.

6. Example Calculation

If a FAHU is designed for 300 Pa pressure drop across filters but readings show 500 Pa, this means:

- Filters are dirty.

- Fan motor consumes more power.

- Airflow may drop below required ventilation rates.

Action: Replace or clean filters immediately.

7. Maintenance Schedule (Typical)

| Component | Check Frequency | Action |

|---|---|---|

| Pre-Filters | Monthly | Wash/replace if ΔP > 150 Pa |

| Fine Filters | Quarterly | Replace if ΔP > 250 Pa |

| HEPA Filters | 6–12 months | Replace if ΔP > 400 Pa |

| Coils | Every 6 months | Clean fins and drain pans |

| Fans | Quarterly | Lubricate, check belts/VFD |

| Dampers | Quarterly | Inspect operation/actuators |